Making advancements in valve technology with RPVs

Valves are one of the most purchased components in the gas industry, and one of the most overlooked.

Virtually every cylinder or storage tank is equipped with some type of valve. Re-inspection facilities stock thousands of valves for quick replacement. Gas distributors stock multiple boxes of valves on their shelves for replacement of faulty or damaged valves.

Despite the large numbers, this aspect of the gas cylinder business is often an afterthought. This is particularly surprising given that valves are the component of gas cylinders most likely to fail. The use of safety inlets, leaking CGA connectors and overuse cause valve failures in the field on a daily basis.

As one of the leading suppliers of gas cylinders and fire fighting equipment, ZX handles thousands of valve orders for gas distributors and filling plants. They also work directly with gas distributors and filling plant operators in the field, so they hear what works and what doesn’t.

Over time, ZX realized that they could really help their customers better understand the different sizes, types and designs of valves and select the right valve for each application.

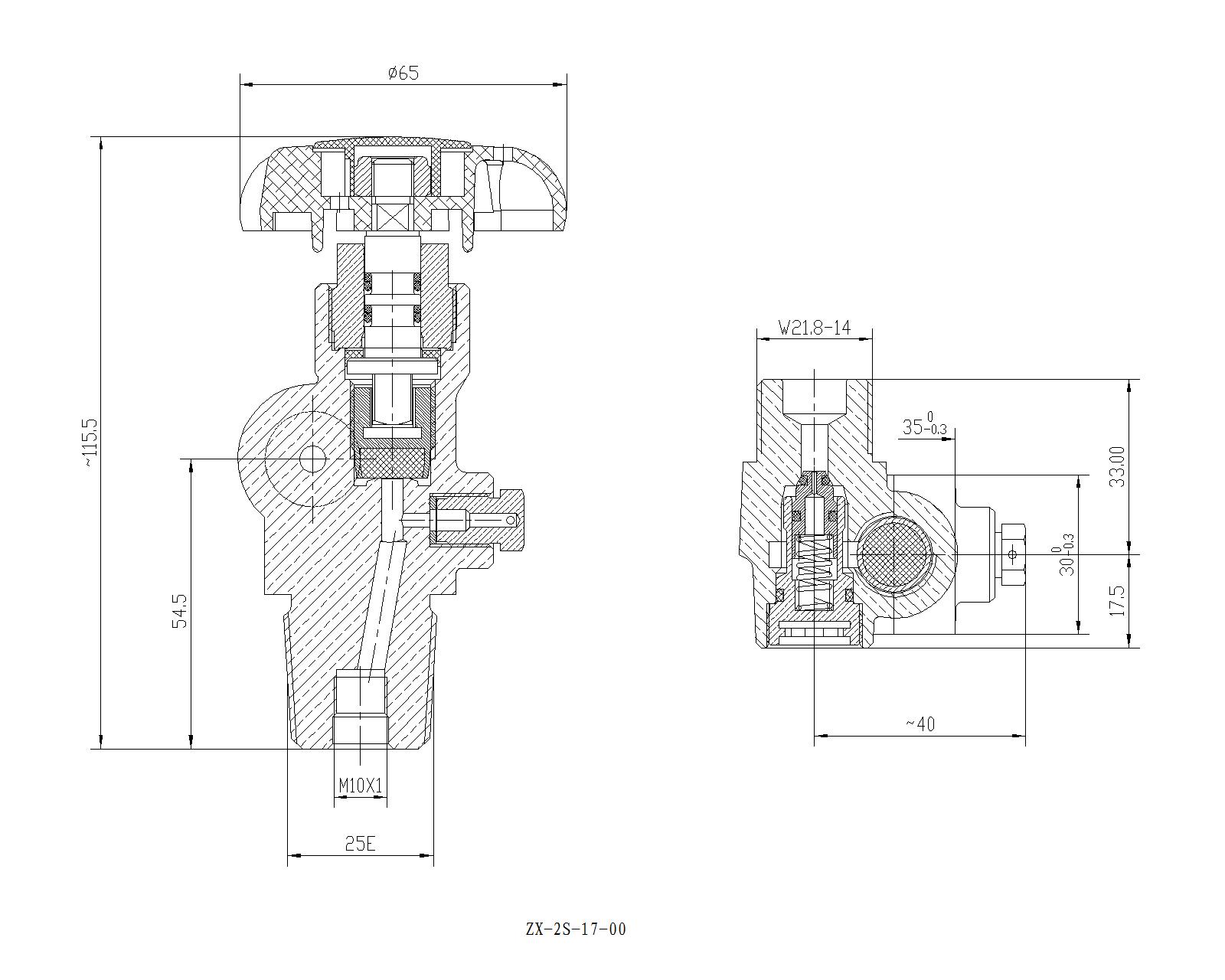

Residual Pressure Valves – A Practical Solution

The residual pressure valve is one of the more relevant recent advances in cylinder valve design and deserves detailed mention.The benefits of the RPV include.1) prevention of backflow contamination, 2) maintenance of high gas quality, 3) reduced internal cylinder maintenance, and 4) increased cylinder life.

Residual pressure valves are available for various gas services such as oxygen, argon, helium, hydrogen, carbon dioxide and special gas mixtures and are suitable for operating pressures up to 300 bar.

The key concept of the RPV is that even if the valve is inadvertently opened, a small positive pressure is retained in the gas cylinder or tank.

Gas distributors already using RPV have been able to minimize or eliminate the high cost of cleaning, draining and internal cleaning of cylinders.

Beverage grade carbon dioxide offers a good opportunity to use RPV. Despite warning notices on CO2 cylinders and tanks, end users rarely follow good practices such as leaving a small amount of positive pressure in the cylinder or closing the cylinder valve after use. This poor practice allows contaminants to enter the cylinders, preventing the filling of qualified beverage grade CO2 and causing corrosion inside the cylinders.

As the industry evolves to ensure delivery of certified beverage grade CO2 to end users, cylinder fillers are turning to RPV to provide their customers with beverage grade CO2 in clean cylinders.

If you have any questions about the RPV, ZX would be happy to help you. ZX offers practical guidance on specific applications and solutions for the RPV as well as other types of cylinder valves.

Post time: Aug-24-2022