factory Outlets for Dip Tube Co2 Tank - ZX TPED Aluminum Cylinder For CO2 – ZhengXin

factory Outlets for Dip Tube Co2 Tank - ZX TPED Aluminum Cylinder For CO2 – ZhengXin Detail:

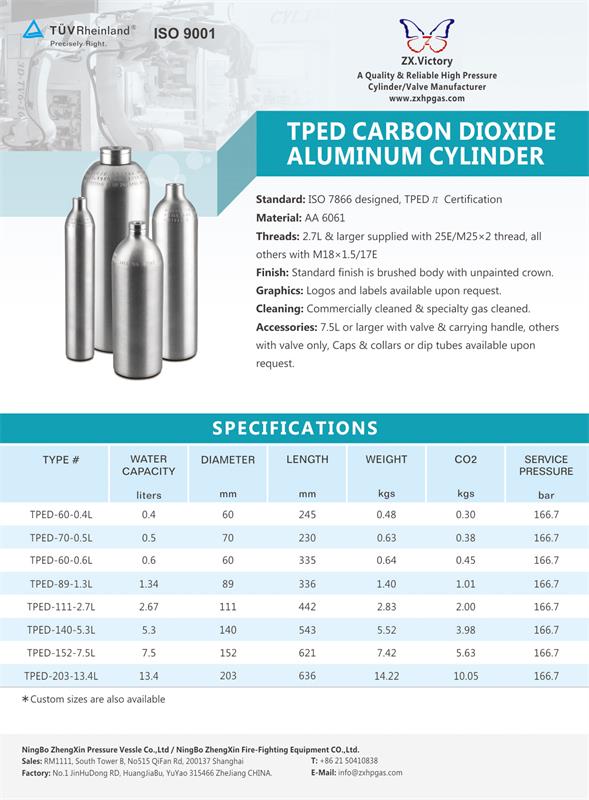

ZX TPED aluminum cylinders are designed and made to be up to ISO7866 standard’s requirements. With a π mark on the cylinder’s shoulder stamp which is certified by TUV, ZX cylinders are sold to many countries around the world.

The main material to produce ZX aluminum cylinders is aluminum alloy 6061-T6. We apply advanced spectrum analyzer to detect the material ingredients thus ensure the product quality.

For ZX TPED CO2 cylinders with 111mm diameter or larger, we recommend 25E cylinder threads, while for others 17E or M18*1.5 will be good.

Surface Finish: It’s available to customize the surface finish of ZX cylinders. We can provide several options for it: polishing, body painting and crown painting, etc.

Graphics: Labels, surface printing and shrink sleeves are the choices for adding graphics or logos to the cylinder.

Cleaning: Food grade cleaning is adapted to ZX cylinders by the usage of our ultrasonic cleaners. The inside and outside of the cylinders are thoroughly washed with pure water under 70 degree temperature to ensure that the cylinders are suitable for food or beverage use.

Accessories: For cylinders with larger water capacity, we recommend plastic handles to make it easier for you to carry the cylinders by hand. Plastic valve caps and dip tubes are also available for protection.

Automatic Production: Our automatic shaping machine lines will guarantee smoothness of the cylinder interface,thus increase its safety level. High-efficiency automatic processing and assembling systems enable us to have both production capacity and short production time.

Sizes Customizing: We can accept orders of custom sizes, as long as it’s inside our certification range. Please provide the detailed specifications of the product you need, and we will design the technical drawings for you.

| TYPE# |

Water Capacity |

Diameter |

Length |

Weight |

C02 |

Service Pressure |

|

liters |

mm |

mm |

kgs |

kgs |

bar |

|

| TPED-60-0.4L |

0.4 |

60 |

245 |

0.48 |

0.30 |

166.7 |

| TPED-70-0.5L |

0.5 |

70 |

230 |

0.63 |

0.38 |

166.7 |

| TPED-60-0.6L |

0.6 |

60 |

335 |

0.64 |

0.45 |

166.7 |

| TPED-89-1.3L |

1.34 |

89 |

336 |

1.40 |

1.01 |

166.7 |

| TPED-111-2.7L |

2.67 |

111 |

442 |

2.83 |

2.00 |

166.7 |

| TPED-140-5.3L |

5.3 |

140 |

543 |

5.52 |

3.98 |

166.7 |

| TPED-152-7.5L |

7.5 |

152 |

621 |

7.42 |

5.63 |

166.7 |

| TPED-203-13.4L |

13.4 |

203 |

636 |

14.22 |

10.05 |

166.7 |

Product detail pictures:

Related Product Guide:

Our eternal pursuits are the attitude of "regard the market, regard the custom, regard the science" plus the theory of "quality the basic, have faith in the main and management the advanced" for factory Outlets for Dip Tube Co2 Tank - ZX TPED Aluminum Cylinder For CO2 – ZhengXin , The product will supply to all over the world, such as: Rome, Bhutan, Orlando, We care about every steps of our services, from factory selection, product development & design, price negotiation, inspection, shipping to aftermarket. We have implemented a strict and complete quality control system, which ensures that each product can meet quality requirements of customers. Besides, all of our products have been strictly inspected before shipment. Your Success, Our Glory: Our aim is to help customers realize their goals. We are making great efforts to achieve this win-win situation and sincerely welcome you to join us.

Company director has very rich management experience and strict attitude, sales staff are warm and cheerful, technical staff are professional and responsible,so we have no worry about product,a nice manufacturer.